We should warn you right away that this article will talk about industrial digital printing on stoneware. If you decide to print several panels for your apartment, then you will need to use other, more popular technologies that exist on the market today, of which we will try to tell you shortly.

So, for many years, pattern printing on stoneware was done using the Rotocolor machine. Rotocolor placed images on tile using rollers and tile that went through them was stamped with a specific image. This is quite convenient, but limits the variety of images, which led to the fact that a lot of tile was produced with similar patterns. Trying to step away from this limitation and searching for a way to better translate the beauty of different images, a new generation of machinery was developed. Such machinery prints on tile using inkjet ink and its first examples were introduced at Cevisama in Spain in the year 2000. Since then, in large due to high competition between manufacturing companies to win over the ceramic market, equipment, printing technologies, dyes, pigments and solvents have been greatly revolutionized.

Today, several companies are ready to offer you a machine that can operate 24 hours per day and produce between 1000 and 1500 square meters of tile per hour, depending on the resolution that you desire. Such equipment easily fits into tile glazing production line. A printing unit can have up to 1000 nozzles, work simultaneously with six different colors and print up to 1000 dpi (for comparison, having 200-300 dpi is more than enough for an image printed on ceramic tile).

Advantages of digital printing vs. Rotocolor.

The main advantages digital printing equipment when compared to a traditional Rotocolor are as follows:

- an absolute stability of the image

- great savings on pigment

- there is no necessity to produce printing forms

- it is possible to reproduce natural and other textures in a photographic quality

- it takes a minimal amount of time to change the image and colors used

- the time is shortened between the time an idea is born and the product is made

Can such a printer do it all? Today, such equipment cannot replace the traditional Rotocolor only if it is necessary to print intensely, or if a very thick coating of dye is required. However, the process to improve these factors in digital printing is on its way.

Inkjet printing technologies

During the inkjet printing process there is no direct contact of the printer with the surface of the tile. The most popular technology that has been accepted by most manufacturers is called Drop-On-Demand, or DOD. It is based on piezoelectric elements that are deformed under the influence of electricity, which causes ink droplets to be squeezed out.

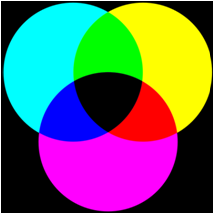

CMYK is the most popular color system that is used by printers throughout the world. CMYK is an abbreviation of the first letters of four colors – Cyan, Magenta, Yellow, blacK. Black is denoted by a K and not a B so that no one thinks that it is Blue. Ideally, when cyan, magenta, yellow and black are combined, you should be able to get any color (depending on the ration), and if you combine them in equal amounts, you should get deep black. But this theory doesn’t prove itself in practice and when these colors are mixed in printing, you only get a dirty, muddy brown. In order to avoid this look, black was added to the mix. As such, from a combination of these four base colors, you can get any color that exists in nature with some exceptions, which is why sometimes other colors are added in the printing process.

Depending on how many colors are supported by a printer (3, 4, 6), a needed amount of color layers is created in the process of color separation. The final image is received by layering different colors of ink on top of each other.

|

|

The same system is used to print on tile, but instead of regular ink, special tile painting pigments are used and a special printing turret, which is constructed so that the nozzles cover the entire width of a tile, is used to raise production levels (more than 1000 square meters per hour).

Tile printing equipment

Today, several manufacturers will be happy to offer you equipment for printing on tile.

KERAjet by Ferro and Gamma printer from Durst

DWD 065 from SACMI and Jet Digital Printer 08 made by TSC

Rotodigit from System and CretaPrinter from Cretaprint

Production printers

Manufacturers of triple baked tile have used inkjet technology from the moment it was created and it is obvious that the demand for such technologies will only continue to grow. Factories can create tile of almost any size with a photograph printed on it, using 3, 4 or 6 main colors. This technology is irreplaceable when putting an image on a grainy surface, since there is no contact of the equipment with the surface. It’s possible to create amazing effects of partially translucent colors and diffusions. Besides, specifically with triple baked tile, this technology allows manufacturers to really lower the use of expensive pigments. This technology is also becoming more and more popular with single baked tile.

Dye and colors

Inkjet printers work with 3, 4, or 6 main colors, and all other colors are supposed to come out from a mix of these. However, this goal has not been yet completely achieved. Traditional ceramic tile dyes are created in limited colors and during their creation, inorganic pigments, or diluted salts are used. Although in the last several years, dyes that ensure stable color have been developed, some specific colors remain to be out of rich for tile manufacturers. For example, there is still no true purple or black and to create them, manufacturers often have to use mixes of other colors.

If you add the great amount of requirements for ceramics dyes - that they can’t change color under the temperature of up to 1200 degrees, have to form very small droplets, can’t clog nozzles and have to be absolutely ecological – it is quite obvious that manufacturers still have a lot to work on to create a perfect dye.

After the completion of Cersaie 2010 we can see that digital inkjet printing technologies for tile are demanded and popular. Leading international manufacturers have already stocked up on, installed and started to use such equipment and it is obvious that demand in such technology will only continue to grow. Nevertheless, today, such technology is far from being perfect, though equipment manufacturers are working intensely on ironing out any bugs. Evidently, in the near future, we will see flowers and peacocks on tile at each exhibition booth, but for now, we have to be happy with what we get – marble and wood images.

Read also:

Imitation wood Xilema stoneware from Cisa